Torque Arms With Position Feedback Sensors for Industrial Assembly Tools

- Designed specifically for INTEGRATORS and MACHINE BUILDERS who provide their own controls.

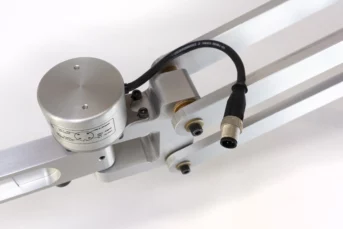

- Feedback of X and Y positions on all models.

- Z axis position analog feedback available with all models. This option is also available to quickly add on to any existing ETA Arm.

- Pitch and yaw analog feedback also available for driving fasteners at off-vertical angles.

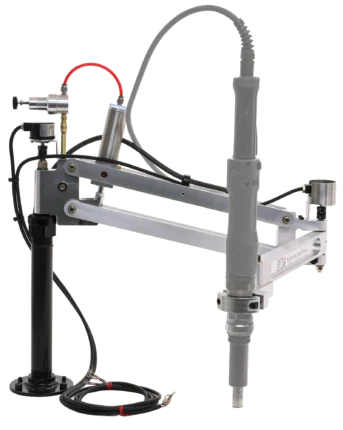

- 7 Standard Frame Sizes Eliminate Torque Reaction and Weight of DC Tools from 1-125 Nm (1 to 1,100 in-lbs) of torque and 1 to 25 lbs of tooling.

- 21 Standard Tool Holders. Custom tool holders also available.

- Also used with Rivet-Nut and Blind Rivet Tools.

- 4 Encoder Output Options offered; plus Encoder-Ready Models.

- Shipped Fully Assembled via UPS Ground, ready to install.

- Quick Delivery.

- Priced Competitively for Integrators and Line Builders.

- Useful for error-proofing and integrating IIoT connected machines.

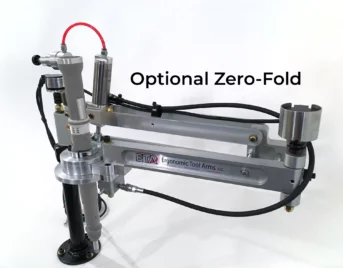

- Customized Arms also available.

- 5-Year Mechanical Wear-Out Warranty.

- Made in U.S.A.

About ETA Smart Arms

Since we introduced our Smart Arms back in 2013, our product offering has grown twenty times over and adapted to suit customer needs. With 7 different frame sizes, 21 different tool holders and 4 different encoder outputs plus custom arm options, we can handle almost any Smart Arm project you have within our size limits.

ETA conventional torque arms, without position feedback, are found in almost all of their configurations at ToolArms.com. ETA Smart Arms are the same footprint and function as our conventional torque arms with the addition of integrated Absolute Encoders for position feedback.

This position feedback of smart torque arms is essential to error-proof human assembly of products that use threaded fasteners, rivets, rivet-nuts and more. With ETA Smart Arms you have torque abatement, tool flotation, tool alignment and location feedback…. which, when combined with an intelligent tool, provides Industry 4.0 compliance in manual assembly operations.

ETA Smart-Arms are built specifically for Integrators, Machine Builders and In-house Tooling Groups who prefer to integrate the outputs from our encoders directly into their own PLC rather than purchase a complete system with a standardized (and expensive) control box from the other Smart Arm manufacturers.

Typically, the PLC or PC already planned on a project can handle communication between the Smart Arm and the tool controller I/O …. Saving many thousands of dollars at each station. Once the logic is written for the first arm, the integration costs for additional stations is minimal. If you aren’t familiar with how Smart Arms work, see Typical Smart Arm Strategy for more information.

We manufacture our Smart Arms in hundreds of model configurations in our Pennsylvania factory. We can adapt to virtually any assembly application with one of those standard models; or we can customize, as necessary. Each model can be ordered in your preference of 4 different encoder outputs (or encoder ready if you prefer to mount your own encoders on our smart-arms). To get a better idea of all the mechanical possibilities go to EL Series Arms . If you see the conventional model on torquearms.com that fits your application, it becomes a smart arm by adding the smart-arm suffix… GCSA, AVSA, AMSA, IOSA or XXSA.

Or, if you prefer, just give us a call, tell us about your assembly application, and we will help you get started. Plus we can send you 3D CAD models, and get you in touch with one of our local sales engineers in your area.

855-866-5276 (855 ToolArm)

All major mechanical components are designed and produced in the US, stocked on site and then assembled to your order.

All ETA arms are backed by a 5 year warranty against excessive or premature wear and part breakage.

Get in touch with us today

Ergonomic Tool Arms, LLC

P.O. Box 534

Doylestown, PA 18901

Phone: 855 TOOL ARM

Phone: (855) 866-5276

contact@toolarms.com

All rights reserved to SmartArms.com